GENERAL DESCRIPTION

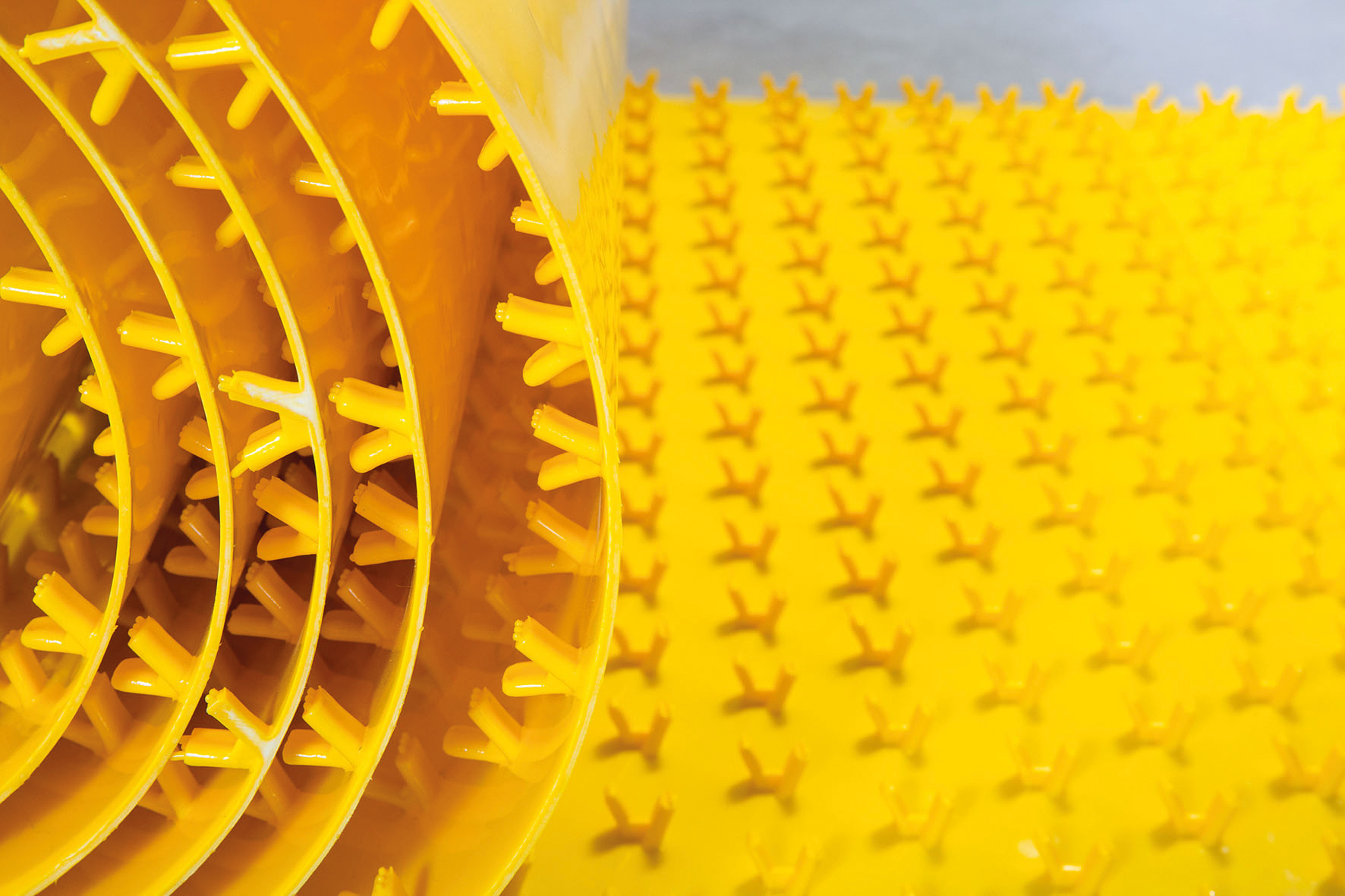

PPP’s V-Lock, T-Rib liners, and welding strips are produced from the finest raw materials. They are produced from proprietary blend of Polyethylene in LLDPE and HDPE.

Our liners are noted for the superior tensile strength and minimal reaction to Chemical Exposure (See Test report Section).

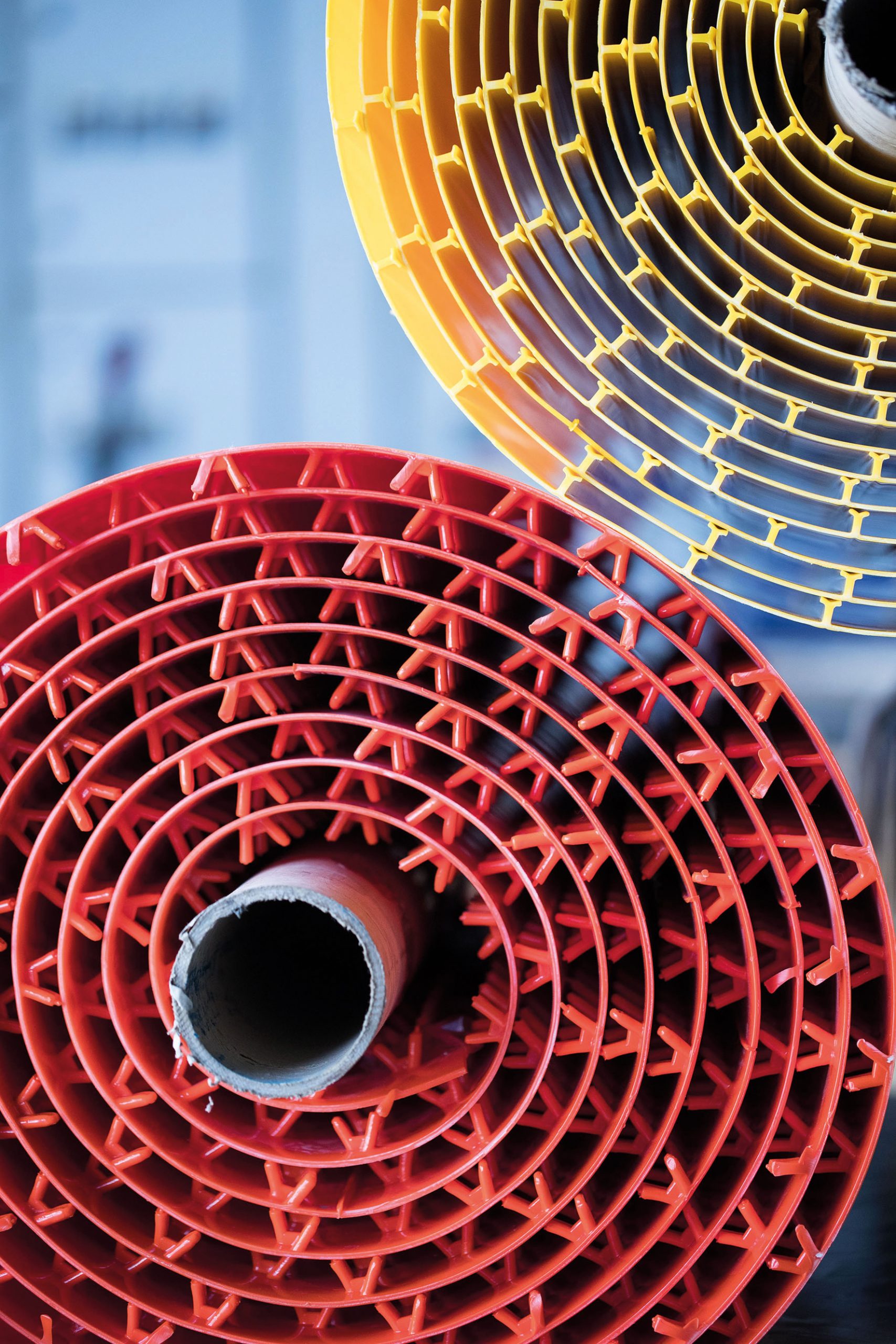

Our V-Lock and T-Rib Lining and plain sheets, are extruded under careful heat and pressure, to ensure a high molecular weight.

They are thermoplastics and will remain flexible within a wide range of temperatures.

PPP’s products are stable throughout wide band of temperatures, making it user friendly and easy to work with.

They have excellent abrasion resistance and are impermeable.

They can be welded at any time during its lifespan.

Typical Use

V-Lock and T-Rib are generally used for lining concrete pipes of all types, concrete tunnels, sumps, grit chambers, clarifiers, wet wells, manholes and chambers.

Our V-Lock and T-Rib are the primary choice of Wastewater and Environmental Utilities, where long term protection performance for economic price are required.

Wastewater Treatment Linings are fabricated into correct sized blankets, placed onto the formwork. Concrete is poured, in a manner, that after removal of the formwork, the V’s and T’s are embedded in the concrete.

Also ideal as tank/container liner for a wide range of chemicals. It can withstand continuous immersion up to 71°C (depend on type and concentration of chemical).

Physical Data

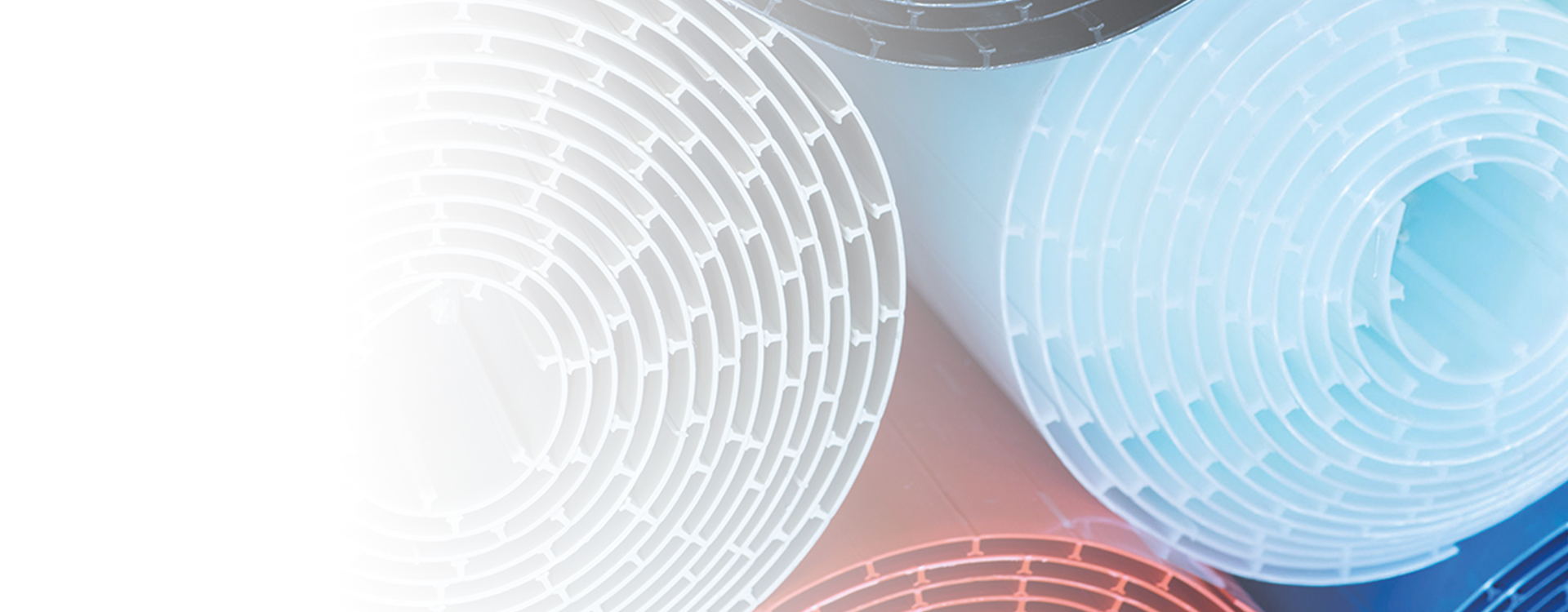

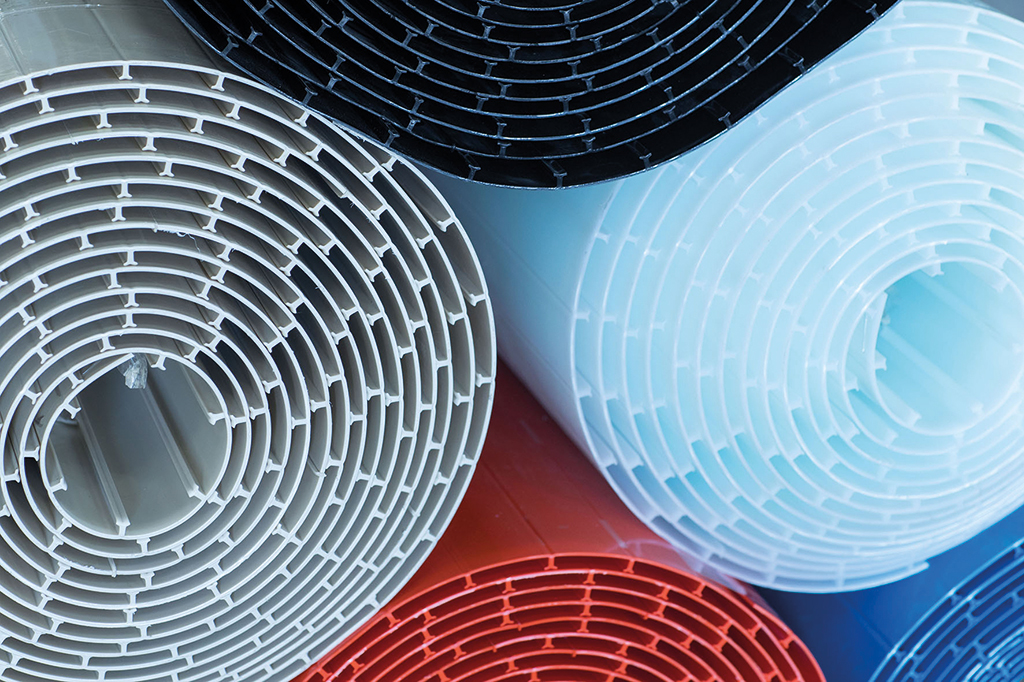

Colors:

Standard colors are Black and White. Other colors can be produced to Customer Specification

Sizing:

Standard Size: Extruded width is 1070 mm. (can be butt-welded to customer’s specifications) with maximum length of 5000 mm.

For example:

Rolls: width 1.200 mm. x 50 meter (60 m²)

Rolls: width 2.000 mm. x 50 meter (100 m²)

Rolls: width 5,000 mm. x 50 meter (250 m²)

Thickness:

- 1.50 mm

- 1.65 mm

- 2.00 mm

- 2.50 mm

- 4.00 mm

Chemical Resistance Properties

PPP’s V-Lock, T-Rib, and Plain Sheet HDPE linings, have excellent acid resistance performance in most mineral acids and in specific organic acids.

Our liners offer excellent resistance to most salts, including copper sulphate, calcium chloride, rock salt and alum.

They also have excellent resistance to Sodium Hydroxide (Dilute) at ambient temperatures.

PPP’s Polyethylene produced with the best resins, can withstand immersion in the following chemicals at the temperatures shown, for a period of one year or more. These materials will discolor in some applications, and even swell or harden. However, this do not mean the material has failed. As left alone, it may well perform for many years.

In plating solutions, HDPE will withstand continuous immersion at normal conditions and temperatures of, up to 55°C

Brass

Bronze

Cadmium

Chromium (all types)

Copper (Cyanide)

Copper (Acid)

Copper (Flouburate)

Gold

Indium

Iron

Lead

Lead Tin Alloys

Nickel (all types)

Palladium

Rhodium

Silver

Tin (all types)

Zinc (Acid)